10 minutes with Ingo Weinert Managing Director at Rotarex SRG

Thank you for taking 10 minutes with gasworld today. Ingo, as a pioneer of capacitance measurement for liquid gases in 1996, why don’t you start by telling us where you see the biggest opportunities for innovation in this space today?

While it is becoming more important than ever to measure liquid gas levels accurately and reliably, traditional solutions such as mechanical float gauges or differential pressure are being replaced by modern digital systems that use capacitance technology. These new systems are more accurate, have no moving parts, and include remote monitoring features that make day-to-day operations much easier and more efficient.

What advantages does capacitance measurement offer over traditional methods?

First, the accuracy: capacitance measurement achieves repeatability within ±1% over the full scale. There’s the advantage of reliability, too, since there are no moving parts, there’s no risk of mechanical failure, and maintenance requirements are minimal. It’s also easy to install in retrofit projects because the probe design can directly replace existing products. And finally, there’s connectivity. These products either have integrated communication features or can be easily connected to existing telemetry systems.

You mention connectivity. How has it changed the way users monitor gas levels?

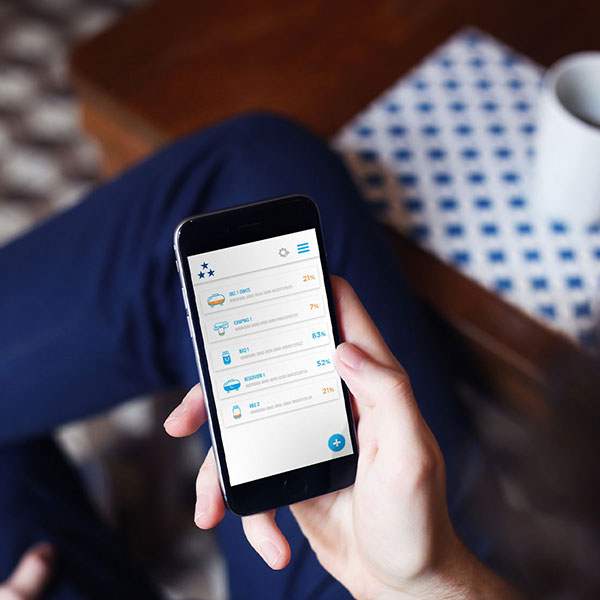

Digital measurement unlocks a whole new level of operational efficiency. Modern capacitance-based systems are now fully compatible with Bluetooth and IoT solutions. This means that fleet managers, facility operators, or even end-users can monitor levels remotely from a smartphone or centralized dashboard. Real-time data acquisition supports just-in-time refilling, prevents downtime due to unexpected shortages, and enhances supply chain transparency. In critical settings like hospitals or laboratories, this remote visibility is especially valuable for compliance and safety.

How about reliability and performance under challenging conditions, cryogenic storage, for example?

Capacitance technology is inherently robust. The absence of moving parts means less risk of failure from vibration, temperature fluctuations, or liquid sloshing. To further protect the electronics, our designs incorporate thermal barriers that insulate sensitive components from extreme cold. Whether in cryogenic tanks storing liquid oxygen, liquid nitrogen, or LNG, or in industrial LPG storage, these systems deliver continuous, reliable readings even in the harshest environments.

Looking forward, do you see any limitations? Or is digital capacitance the new norm?

In my view, digital capacitance measurement is the future, and increasingly, the current standard for liquid gas level detection or the present reality of liquid gas level detection. The combination of accuracy, reliability, versatility, and remote accessibility makes it the logical choice for anyone looking to future-proof their operations. While the technology continues to evolve, particularly around connectivity and integration with wider process control systems, the core principle remains unchanged: capacitance delivers one of the best measurements for liquefied gases, period.

It’s often assumed that high-tech digital solutions come with a high price tag. Has cost been a barrier to widespread adoption?

That’s an important point. When we first started developing digital capacitance technology in the 1990s, it was true that advanced sensors and electronics carried a significant cost premium. But one of our driving ambitions has always been to democratize this technology – making it accessible for as many applications and users as possible, not just high-end or mission-critical sectors.

Through continuous innovation, better component sourcing, and economies of scale, we have managed to bring the cost down dramatically over the years. Today, digital capacitance measurement is cost-competitive with traditional mechanical gauges, while offering so much more in terms of accuracy and features.

Explore Our Digital Measurement Solutions – Precision Meets Connectivity

Building on this expertise, Rotarex SRG’s Digital Measurement Solutions deliver accurate, digital level monitoring for all types of gas storage, including cryogenic, propane, and refined fuel tanks. With BLE-enabled wireless access, cloud-based fleet management, and sensor designs without moving parts, it ensures long-term performance, seamless integration, and greater operational visibility across multiple applications.

Learn more about our digital measurement solutions:

- for Cryogenic Tanks : C-Stic Lite & C-Stic Industrial

- for LPG : C-Flex & Refined Fuels : ELG

- Smart Valve for Cylinders