Carbonation, freezing, chilling, inerting and ph control: digital monitoring in beverage and food industries

Although these gases are typically stored in a liquid state (LCO₂, LN₂), their gaseous form is directly used for applications. The gases most commonly used in these industries are LN₂ (liquid nitrogen) and LCO₂ (liquid carbon dioxide). These gases, combined with digital solutions for their use, become even more significant. The implementation of digital monitoring systems plays a vital role in driving innovation and in the development of operational monitoring.

APPLICATIONS IN THE BEVERAGE INDUSTRY

Your favorite drinks, even more sparkling

In the beverage industry, carbonation is one of the best-known applications of CO₂. In beverage production and bottling plants, CO₂ is used in several processes. It can be added to industrially produced beverages, such as water, sodas or other sparkling lemonades. When carbon dioxide is added to water, it becomes sparkling, when added to various drinks, they become fizzy. Thanks to the phenomenon of CO₂ dissolving in drinks, manufacturers create the tangy taste and fizz so appreciated by customers. This is why the CO₂ is indispensable in the beverage industry.

Preserve freshness and flavors

Liquid nitrogen (LN₂) is currently the most commonly used cryogenic gas for creating an inert environment, particularly in wine bottling. LN₂ effectively removes the oxygen present in containers before they are sealed, thus limiting oxidation, microbial proliferation and the alteration of aromas. This process promotes the preservation of freshness and quality over the long term (liquid CO₂ can also be used but is less commonly used).

During beverage production, digital monitoring systems enable accurate measurement of CO₂ content. This ensures safety, reduces waste, and maintains consistent product quality. This is especially important in beverage dispensing applications, commonly found in fast-food restaurants, where customers expect their soft drinks to always have that perfect fizz. Avoiding CO₂ shortages is therefore essential.

APPLICATIONS IN THE FOOD INDUSTRY

A multifunctional partner for food

Carbon dioxide is also important and multifunctional in the food industry. First of all, LCO₂ (often mixed with nitrogen) is used to replace the air contained in food packaging, which prevents products from spoiling and gives them a longer shelf life.

In the preservation of vegetables and the fermentation of cheese, CO₂ slightly reduces the pH of the product and slows down the growth of bacteria and other mold. This considerably improves the preservation of vegetables as well as cheese production.

Your essential for an even more frosty freeze

In the food industry, LN₂ is an essential pillar of freezing and rapid cooling processes. The texture, quality and nutritional value of products are preserved thanks to the ultra-low temperatures of liquid nitrogen. This gas is mainly used in two applications. Firstly, in freezing, where LN₂ enables rapid freezing of perishable products while preserving their freshness. It also helps prevent the formation of ice crystals. Secondly, liquid nitrogen is used to preserve food in the long term through cryogenic storage.

What role does digital measurement system play in these industries?

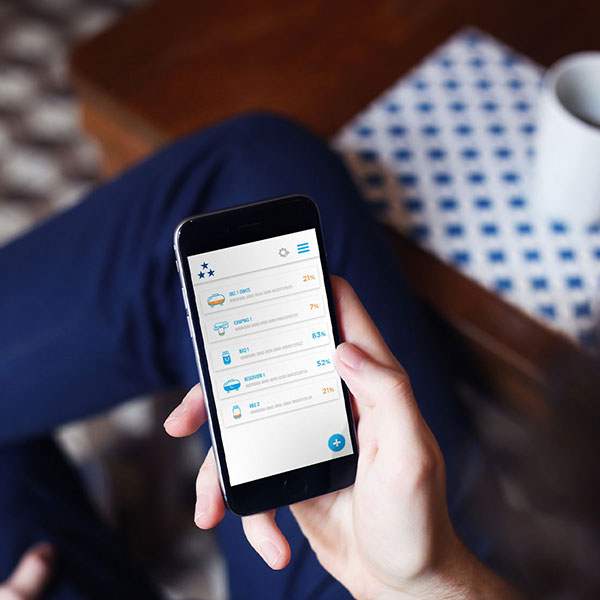

While the role of gases like CO₂ and nitrogen is indispensable in these sectors, digital monitoring systems such as DIMES transform their operations. These solutions allow continuous monitoring of gas content levels, ensuring optimal performance and preventing unexpected shortages. For gas providers, this means complete traceability of storage tanks at all times—whether located at the customer's premises, in transit, or at the warehouse.

But their benefits don’t stop there, these solutions also improve the safety of the surrounding environment. In fact, the risks associated with handling liquefied gases are reduced thanks to the early detection of anomalies or leaks.

In addition, the operational efficiency of DIMES also makes the difference in the management of liquefied gases by significantly reducing operating costs and significantly minimizing waste with the support of automation and accurate control.

Finally, digital monitoring systems ensure compliance through detailed recording of liquefied gas usage and therefore facilitate respect for industry standards and regulations.

In conclusion, ensuring safety and quality in the food and beverage industries requires the use of liquefied gases such as LCO₂ and LN₂. Thus, with the integration of digital monitoring systems such as DIMES, manufacturers can take full advantage of the benefits of these gases. This allows them to maintain control and efficiency in the long term. Ultimately, in increasingly competitive markets, companies expect more and more high-quality products, making digital monitoring technologies essential to maintain a constant advantage.

If you are ready to discover how DIMES® can transform your operations, contact us for more information on this revolutionary solution.