-

SIMPLIFY MEASUREMENT

- Direct replacement for float gauges

- No moving parts enhances reliability and durability

-

IMPROVE ACCURACY

- Accuracy within +/- 1% (over full scale)

- Superior accuracy compared to mechanical or pressure devices

- Thermal barrier to prevent influence of cold temperatures on electronics

-

IMPROVE PRODUCTIVITY

- Help to support better management of customer's supply chain

- Improved profitability with fewer emergency, out-of-product service calls

- Improved efficiencies with more accurate measurements

- Remote monitoring options for data acquisition

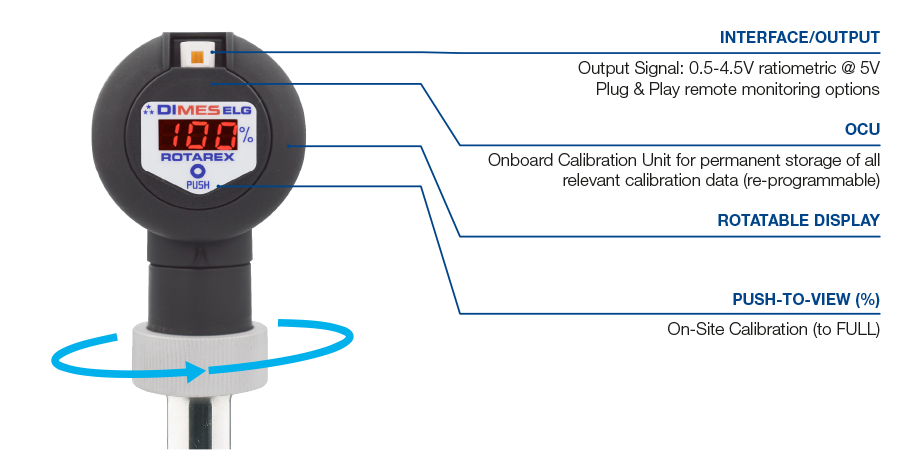

| Material | PA 6.6 Black | |

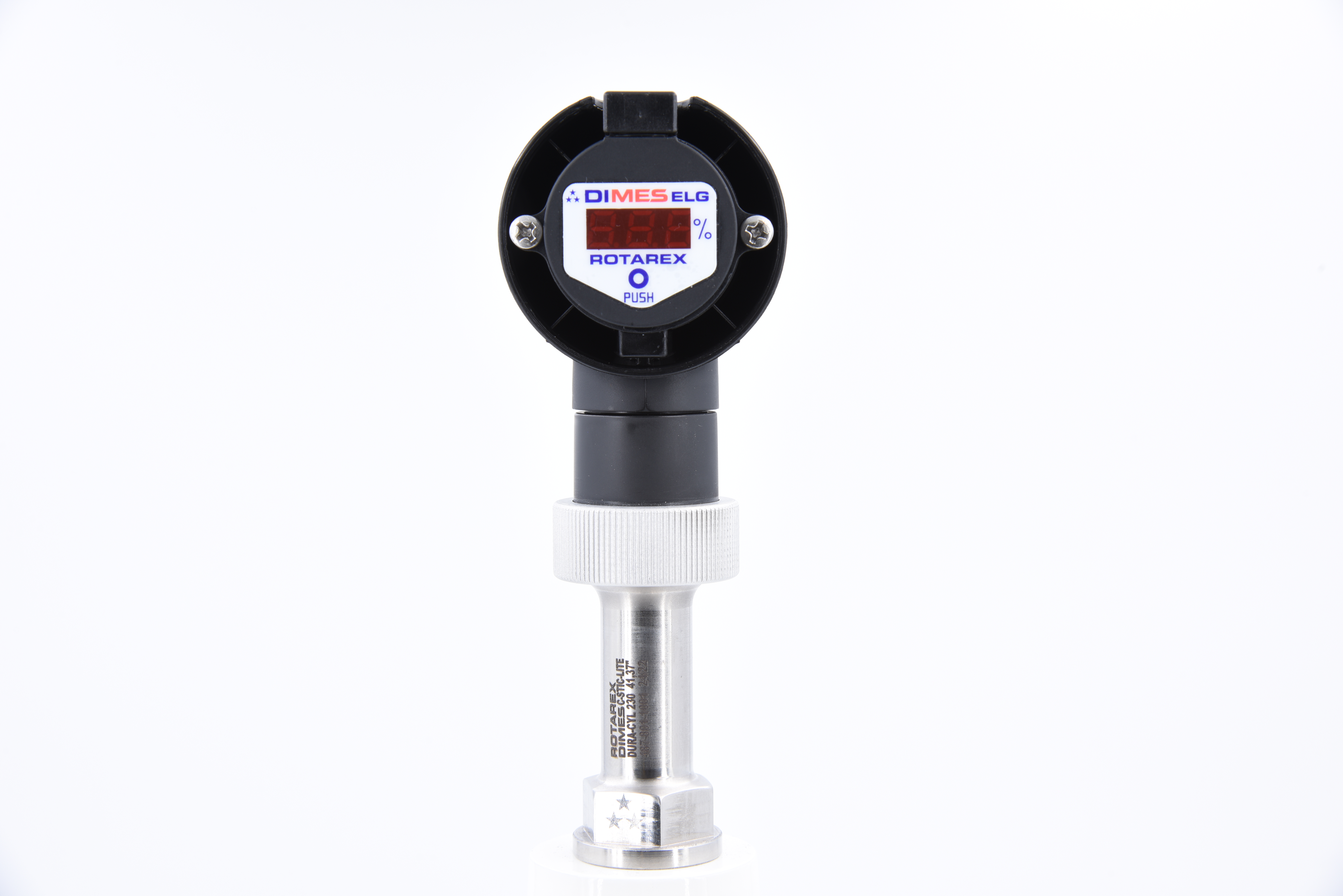

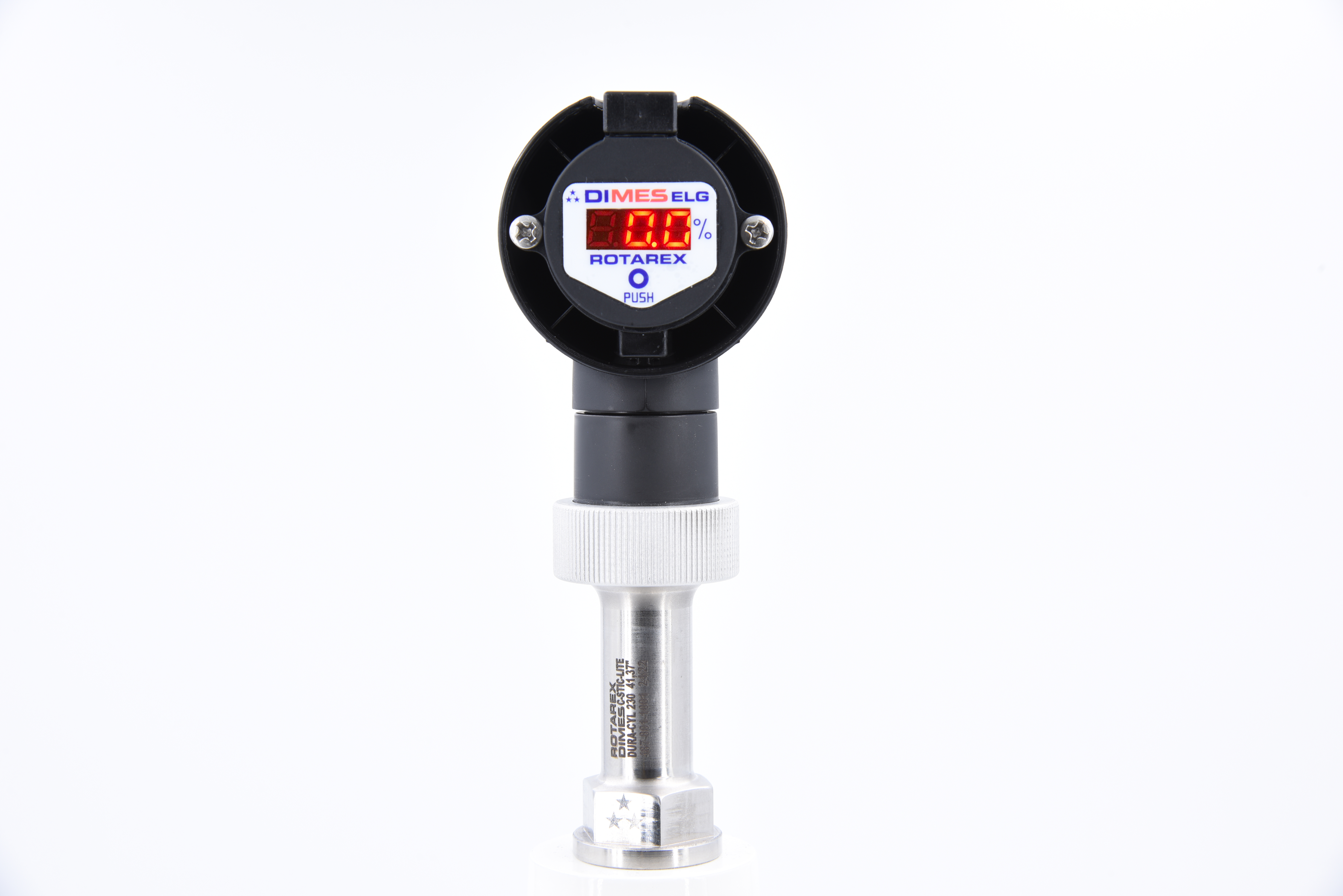

| Display | 3-digit red LED (in % full) | |

| power | Coin-battery 3V (CR2032) External SV (JWPF) |

|

| connections | M35x1 | |

| Communication | JWPF Outlet Connector 0.5-4.5V @ 5V Reading on demand / On-Site full calibration |

|

| Operating temperature | -20 to 60°C (-4°F to +150°F) |

- Description: the display (dial) does not receive a signal (or wrong signal)

- Details: in order to operate properly, the display (dial) must receive the proper signal from the sensor (probe)

- Root Cause: missing intial factory calibration or hardware problem (e.g. broken sensor pins or wrong orientation of the connection cable)

- Suggested resolution: check the sensor pin / check the proper wiring scheme between the sensor and the display (dial) or replacement of the complete C-Stic

- Description: measured sensor value is smaller than empty

- Details: based on the initial factory (empty) calibration, the C-Stic is reading a lower value than originally define (below zero)

- Root Cause: this error-message indicates a factory calibration error or hardware problem

- Suggested resolution: replacement of the complete C-Stic

- Description: measured level is (virtually) beyond 150%

- Details: the C-Stic is reading a value beyond the maximum limit (150%)

- Root Cause: this error-message indicates a wrong "calibration to Full" setting (calibration to full was performed before the cylinder was properly/completely filled) or hardware problem

- Suggested resolution: remove some product from the cylinder until the display reads 100%, now recalibrate to full, then start to fill the cylinder again and repeat the "calibration to full" procedure multiple times during the fill (every 20% of product you add = repeat the calibration to full procedure) or replacement of the complete C-Stic

- Description: first step of the "calibration to Full" sequence

- Details: device entered into the calibration mode

- Note: Please follow the dedicated "calibration to Full" procedure

- Description: second step of the "calibration to Full" sequence;

- Details: user has to confirm to perform adjustment

- Note: Please follow the dedicated "calibration to Full" procedure

- Description: acknowledgement from device on successful adjustment

- Details: this indicates that the calibration to full has been successful

- Note: Please follow the dedicated "calibration to Full" procedure

- Description: feedback from device to indicate unsuccessful adjustment

- Details: no changes have been made

- Root Cause: at very low ambient temperatures the battery power might not be sufficient to perform the full calibration sequence

- Note: Please repeat/follow the dedicated "calibration to Full" procedure (at a later time when the ambient temperature has improved)

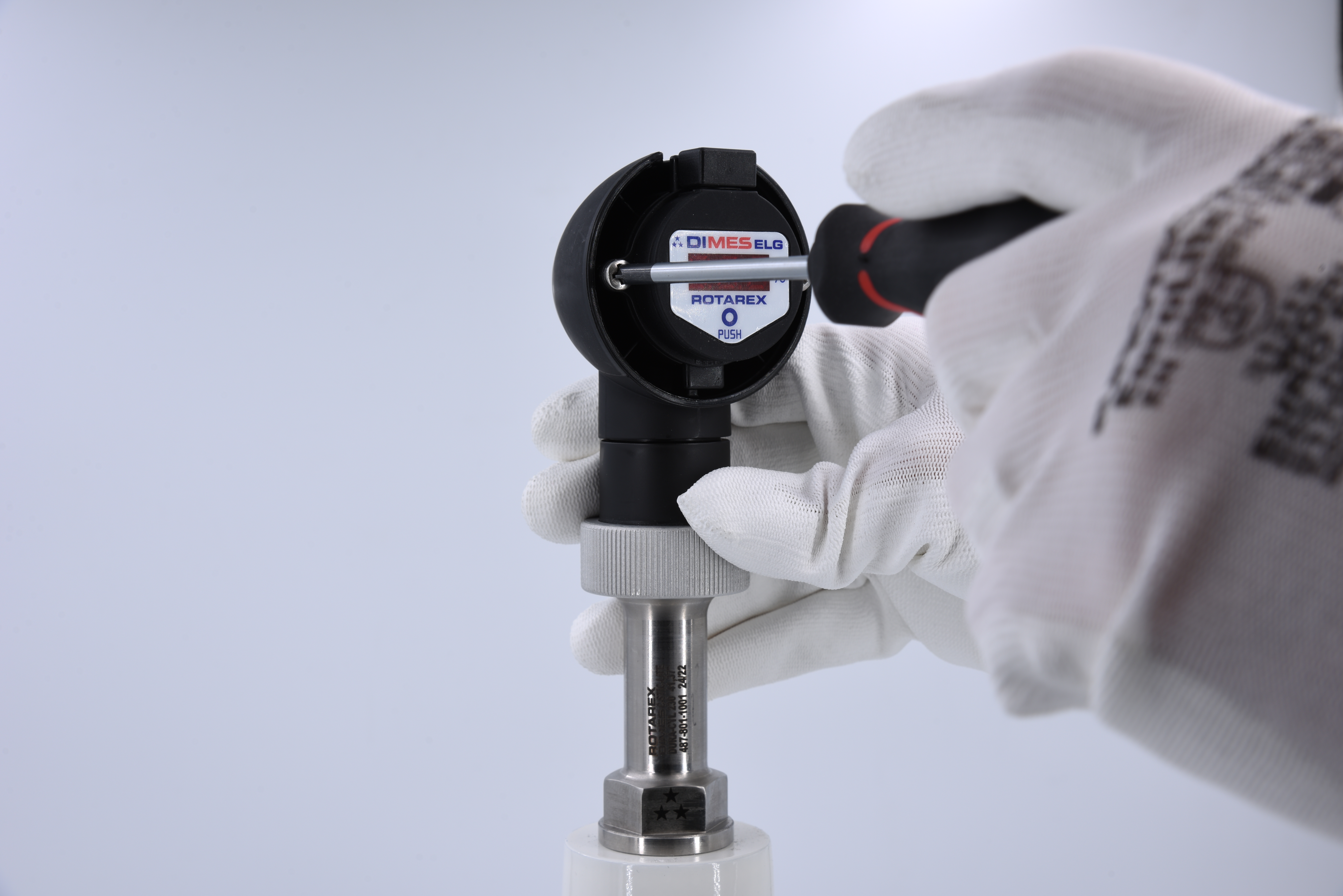

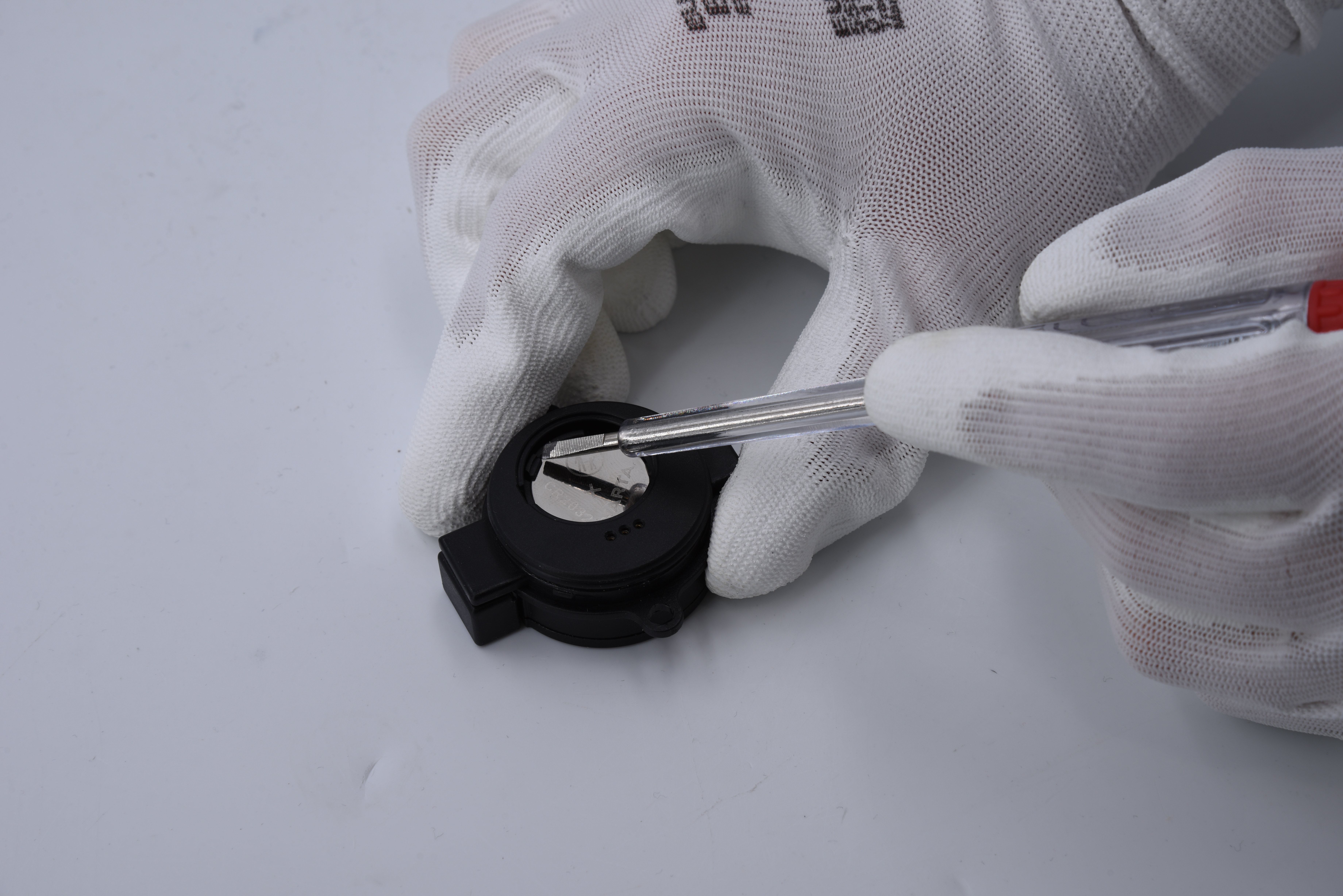

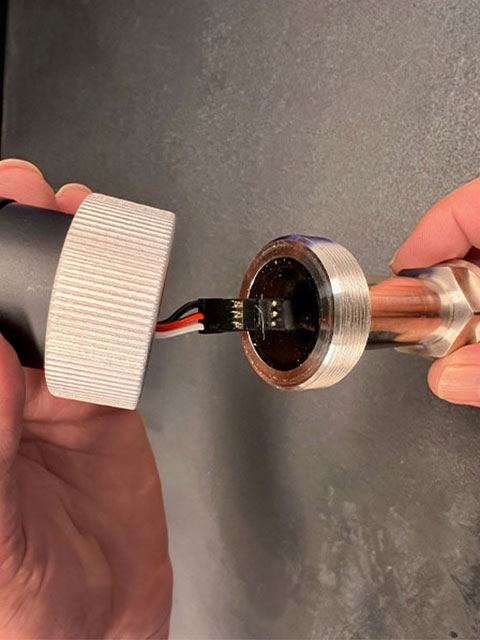

Please use a small flathead screwdriver to press the tab on the connector, then gently pull it out.

Watch the video here.

If battery level is too low for a (reliable) re-calibration, it also shows "Err"

Note: Only use a CR2032 batteries!

Even though the DIMES Cryogenic comes with an industry leading energy management, you may need to replace the onboard battery. Follow the steps below to do so:

You will need the following tools to replace it:

- A coin

- A new battery (only use CR2032 batteries)

- A small flathead screwdriver

- A philipps head screwdriver

Shall you experience a transportation damage – don’t worry the new C-Stic was build to allow easy maintenance & repair

Follow the following steps to repair the rotating display

_dLZDiw.jpg)